Setting up a Pattern Recognition Knowledge

There is a sample knowledge, intended to show the basic setup of Pattern Recognition. This knowledge will use some of the more common aspects of Pattern Recognition so that you can focus on the details of how Pattern Recognition works within a drawing.

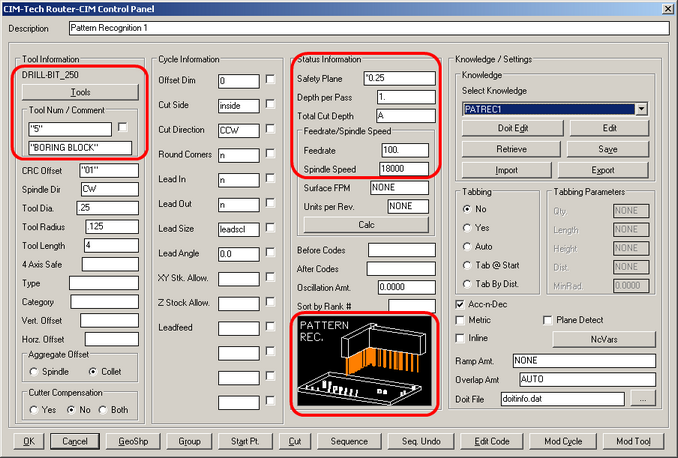

PATREC1

This cycle is set up to use a drill-bit (any size is OK, in this case it is 1/4"). The tool description is changed to read "BORING BLOCK" so that in the code you will recognize the tool call as being from the drill block. The cycle is set to Pattern Recognition, and the Status information is set for the drill block to drill at 100 inches per minute, and the depth will be set according to the thickness given to the holes.

Note: When you post processor was created, there was likely a drill block in the default drawing that loads with Router-CIM. You should use that drawing and set the sizes of the circles in that drawing to match the sizes of the drills in the sample drawing if you are using that as a learning tool.

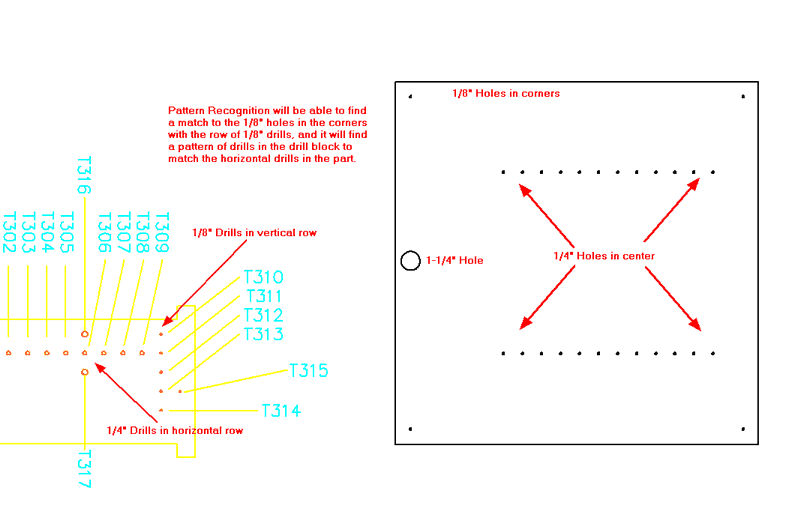

The drawing used for this example has a part with several holes in it, and a drill block with 17 vertical drills. Some of these drills match the holes in the part. There is one hole in the part that is quite large, and there is no drill bit in the boring block that matches that hole.

There is not a lot of work involved with setting up a Pattern Recognition knowledge, but there are a few rules to think about.

| • | You can select ALL of the part at once during cut and patrec will only look for circles that are in the part and look for a match to the circles on the boring block. All other geometry will be ignored. |

| • | Pattern Recognition will try and call as many drills down at once as it can and drill the part with the fewest number of drill hits that it can and still drill all the holes. |

| • | If you have holes with different depths, then you should use multiple patrec knowledges and select holes that have matching depths. Patrec cannot tell the difference between holes of one depth and holes of another when it finds a pattern, it is only looking at the diameter of the circles. |

Once pattern recognition was finished, it found the following matches, a total of 4 drill hits for the 4 holes in the corners, as they were too far away from another other holes to use more than 1 drill at a time. A total of 4 hits on all the center holes, two with 9 drills and two with 3 drills. That is 8 moves for 28 drills with the drill configured as drawn. The large circle was passed because there were no matching drills in the drill block.

N6(BORING BLOCK)

N7G28G91Z0M5

N8G90T314 << 1/8" drill called and hits 4 times.

N9M3S18000

N10G0G17G54P14X1.Y23.

N11G0G43H34Z.25

N12G1Z-.375F100.

N13G0Z.25

N14G0X23.

N15G1Z-.375F100.

N16G0Z.25

N17G0Y1.

N18G1Z-.375F100.

N19G0Z.25

N20G0X1.

N21G1Z-.375F100.

N22G0Z.25

N23(BORING BLOCK)

N24G28G91Z0M5

N25G90T301 << 9 drills called and hit twice for 1/4" pattern.

N26T302

N27T303

N28T304

N29T305

N30T306

N31T307

N32T308

N33T309

N34M3S18000

N35G0G17G54P1X7.1422Y18.

N36G0G43H21Z.25

N37G1Z-.25F100.

N38G0Z.25

N39G0X10.9216Y6.

N40G1Z-.25F100.

N41G0Z.25

N42(BORING BLOCK)

N43G28G91Z0M5

N44G90T302 << 3 drills called and hit twice for 1/4" pattern.

N45T303

N46T304

N47M3S18000

N48G0G17G54P2X18.4804Y18.

N49G0G43H22Z.25

N50G1Z-.25F100.

N51G0Z.25

N52G0X7.1422Y6.

N53G1Z-.25F100.

N54G0Z.25

N55G28G91Z0M5