Setting up the Peck Bore Knowledge

There are two knowledges contained in the Peck Bore sample drawing, which will allow you to see the parameters involved in canned cycle drilling for the Spot Bore cycle.

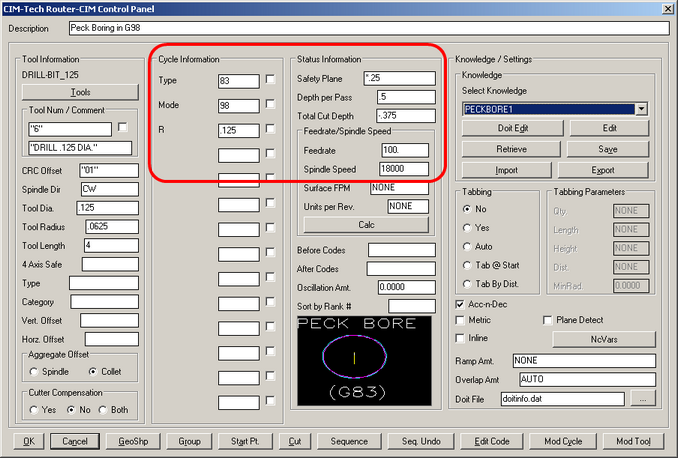

The parameters for Canned Cycles are pretty straightforward, and the Control Panel has very few cycle choices. Selecting the knowledge PECKBORE1 will show the following parameters:

PECKBORE1

Type

Type is set to 83 for Peck Boring. There are several Canned Cycles available and the types are shown here.

Mode

Mode refers to either G98 or G99 mode. You only need to fill in the numeric value. G98 will retract to the initial point between each hole and G99 mode will retract to the R point (set by the next parameter) between each hole.

R

This is the Retract point where the tool can move to between each hole. This is set to a positive Z value above the top of the part where you want the tool to retract to between passes and between each hole in G99 mode.

Safety Plane

The Safety Plane is where the tool starts in Z and also where the tool retract to between drills in G98 mode.

Depth per Pass

This is the depth to drill to for each pass in Z. Typically, Peck Boring is done in multiple passes. Otherwise it would be Spot Boring (see previous section).

Total Cut Depth

This is the depth in Z where the tool is going to stop its drilling and retract.

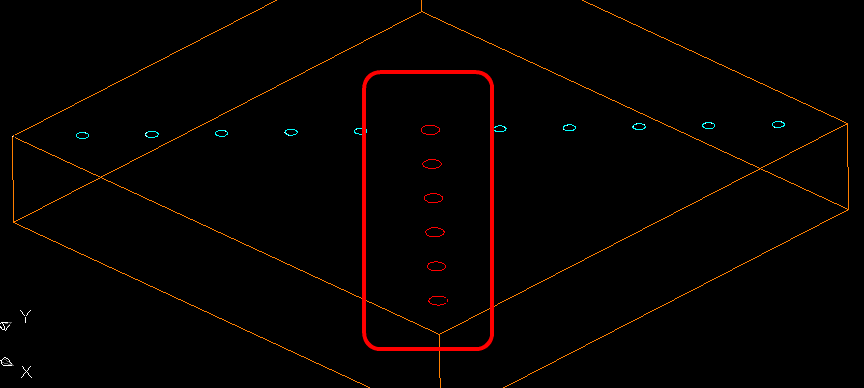

Using these parameters and selecting the row of large holes in the part, shown here:

will produce a tool path and the following code:

%

:1234

N1G00G17G20G28G40G80G91Z0M5

N2G90

N3G52X0Y0Z0

N4G08P1

N5M08

N6(DRILL .125 DIA.)

N7G28G91Z0M05

N8G90T2006M06

N9T102

N10M03S18000

N11G00G17G55X11.Y1.

N12G00G43H5Z.25

N13G98G83Z-.375R.125Q.125F100.

N14X10.Y2.

N15X9.Y3.

N16X8.Y4.

N17X7.Y5.

N18X6.Y6.

N19G80

N20G28G91Z0M5

N21G28G91X0M09

N22G90

N23G52X0Y0Z0

N24G08P0

N25M30

%

This will cause the tool to move to the first hole location (X11, Y1 in this case) and then set the parameters for the canned cycle. Since the Mode was set to 98, in G98 mode the tool will start at Z.25 and retract to that position between holes (regardless of the setting of R). It will drill each hole at a feedrate of 100. inches per minute, in increments of .125 in Z until it reaches the bottom of the hole (-.375) and then retract and move to the next hole until it reaches the G80 command on line N19.

There is a setting for R in the code above, but in G98 mode it is ignored.

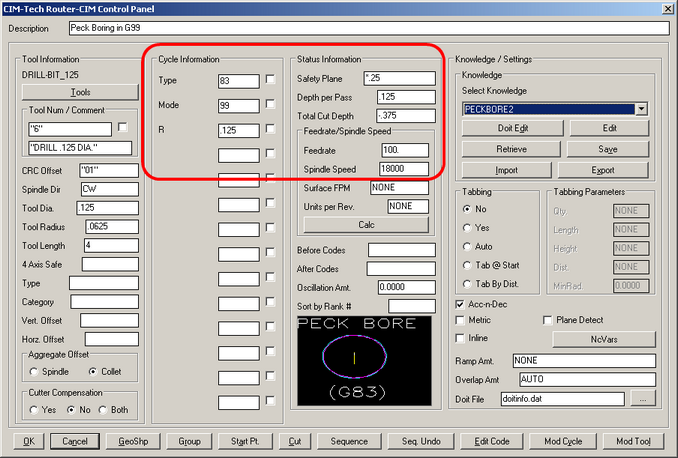

PECKBORE2

Type

Type is set to 83 for Spot Boring. There are several Canned Cycles available and the types are shown here.

Mode

Mode refers to either G98 or G99 mode. You only need to fill in the numeric value. G99 will retract to the R point between each hole, in this case Z.125.

R

This is the Retract point where the tool can move to between each hole. This is set to a positive Z value above the top of the part where you want the tool to retract to between passes and between each hole in G99 mode.

Safety Plane

The Safety Plane is where the tool starts in Z and also where the tool retract to between drills in G98 mode.

Depth per Pass

This is the depth to drill to for each pass in Z. Typically, Peck Boring is done in multiple passes. Otherwise it would be Spot Boring (see previous section).

Total Cut Depth

This is the depth in Z where the tool is going to stop its drilling and retract.

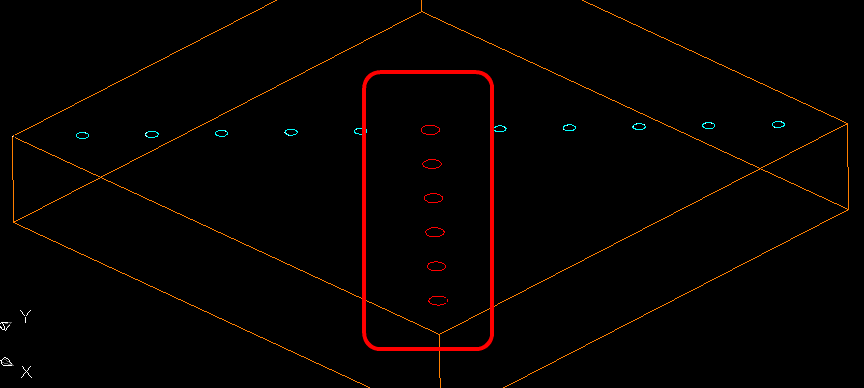

Using these parameters and selecting the row of large holes in the part, shown here:

will produce a tool path and the following code:

%

:1234

N1G00G17G20G28G40G80G91Z0M5

N2G90

N3G52X0Y0Z0

N4G08P1

N5M08

N6(DRILL .25 DIA.)

N7G28G91Z0M05

N8G90T2006M06

N9T102

N10M03S18000

N11G00G17G55X11.Y1.

N12G00G43H5Z.25

N13G99G83Z-.375R.125Q.125F100.

N14X10.Y2.

N15X9.Y3.

N16X8.Y4.

N17X7.Y5.

N18X6.Y6.

N19G80

N20G28G91Z0M5

N21G28G91X0M09

N22G90

N23G52X0Y0Z0

N24G08P0

N25M30

%

This will cause the tool to move to the first hole location (X11, Y1 in this case) and then set the parameters for the canned cycle. Since the Mode was set to 99, in G99 mode the tool will start at Z.25 and retract to Z.125 between holes (because of the setting of R). It will drill each hole at a feedrate of 100. inches per minute, until it reaches the G80 command on line N19.