Setting up fast vertical drilling knowledge.

There are two sample drill cut knowledges in the FastDrill sample drawing. Each of them is designed to show a slightly different configuration to drilling.

FastDrillOnePass

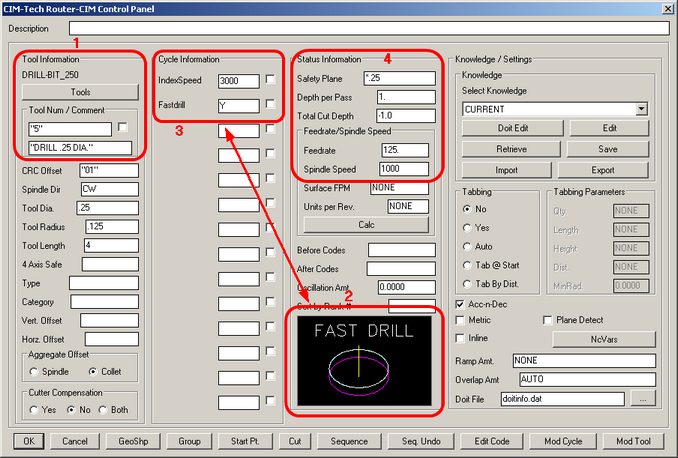

Setting up the FastDrillOnePass knowledge is pretty simple. The steps are:

| 1. | Select a drill bit from the tool list. Use a tool number that is valid for your machine to drill with. |

| 2. | Select the Fast Drill cycle. The center column of the Control Panel will change to show the Fast Drill Options. |

| 3. | Set the IndexSpeed to the fastest feedrate your machine can maintain. Then set Fastdrill to 'Y' to turn this option on. |

| 4. | Change your Status settings as necessary to drill the holes desired. In this instance, there is a Safety Plane of .25 above the part, and a Total Cut Depth of -1.0", which will be made in one pass at a feedrate of 125. Inches Per Minute. |

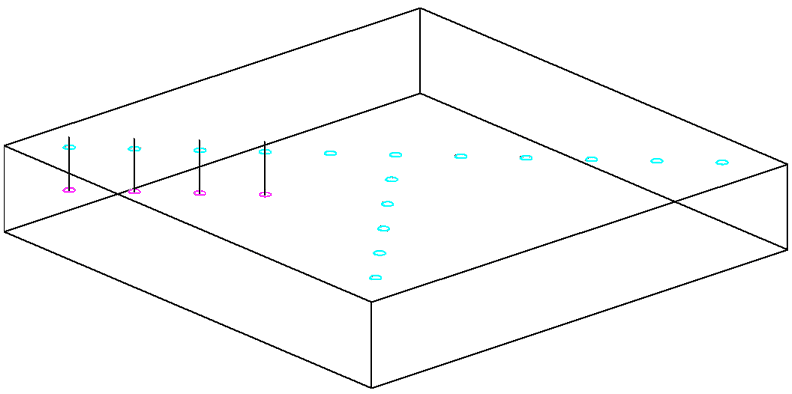

Using this knowledge and selecting a few holes to drill will show the following result:

This will result in the following code:

(DRILL .25 DIA.)

G28G91Z0M05

G90T2005M06

T102

M03S1000

G00G17G55X1.Y1. <<-- Index to first cut position.

G00G43H5Z.25 <<-- Bring cutter to .25 above the part.

G01Z-1.F125. <<-- Drill the first hole at 125 Inches Per Minute.

G01Z.25F3000. <<-- Move back up in Z to the Safety Plane at 3000 IPM.

G01X2.Y2.F3000. <<-- Index to next hole location at 3000 IPM.

G01Z-1.F125. <<-- Drill the next hole at 125 IPM.

G01Z.25F3000. <<-- Move back up in Z to the Safety Plane at 3000 IPM.

G01X3.Y3.F3000. <<-- Index to next hole location at 3000 IPM.

G01Z-1.F125. <<-- Drill the next hole at 125 IPM.

G01Z.25F3000. <<-- Move back up in Z to the Safety Plane at 3000 IPM.

G01X4.Y4.F3000. <<-- Index to next hole location at 3000 IPM.

G01Z-1.F125. <<-- Drill the next hole at 125 IPM.

G01Z.25F3000. <<-- Move back up in Z to the Safety Plane at 3000 IPM.

G28G91Z0M5

The machine will drill these holes faster than it would if the move in Z to the safety plane and the index to the next location were performed in Rapid Traverse or G0 mode.

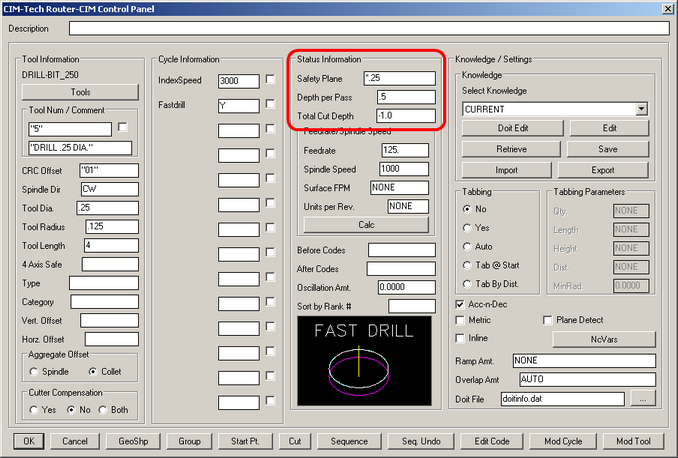

FastDrillTwoPass

Changing the knowledge to make two passes in Z and still use the FastDrill technology is pretty simple. Change the Depth Per Pass to .5 with a Total Depth of -1.0 and you will get two passes in each cut.

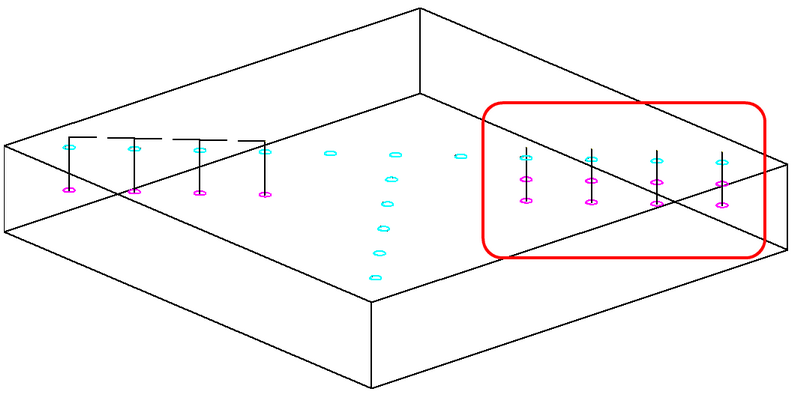

These settings will cause the tool to make two passes in Z, with the result looking like the following image.

And Sequencing these holes will result in the following code:

(DRILL .25 DIA.)

G28G91Z0M05

G90T2005M06

T102

M03S1000

G00G17G55X8.Y8. <<-- Index to hole location.

G00G43H5Z.25 <<-- Move in Z to .25 above the part.

G01Z-.5F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01Z-1.F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01X9.Y9.F3000. <<-- Index to hole location.

G01Z-.5F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01Z-1.F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01X10.Y10.F3000. <<-- Index to hole location.

G01Z-.5F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01Z-1.F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01X11.Y11.F3000. <<-- Index to hole location.

G01Z-.5F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G01Z-1.F125. <<-- Drill the hole at 125 IPM.

G01Z.25F3000. <<-- Move in Z to .25 above the part.

G28G91Z0M5