Making Tool Paths and Code

The next step in this sample is to apply the toolpaths to the part and create nc code if necessary. In order to do this, you will use the DOIT cycle.

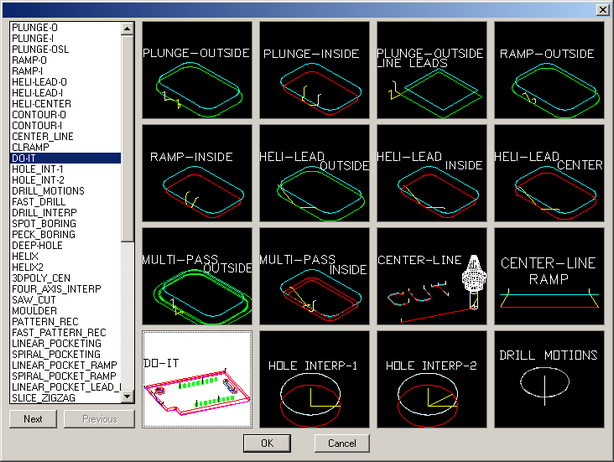

Select the cycle picture on the Control Panel and choose DOIT from the available cycles.

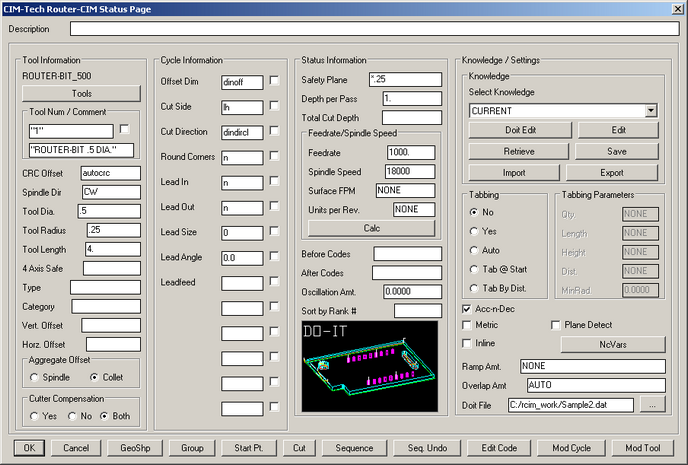

Returning to the Control Panel, you should be ready to start the DOIT process.

Select the CUT button on the Control Panel, you will be prompted to Select Objects. At this prompt press ENTER to continue. Router-CIM will create tool paths on all your shapes and when it is finished, you will see the following prompt:

Select YES to continue.

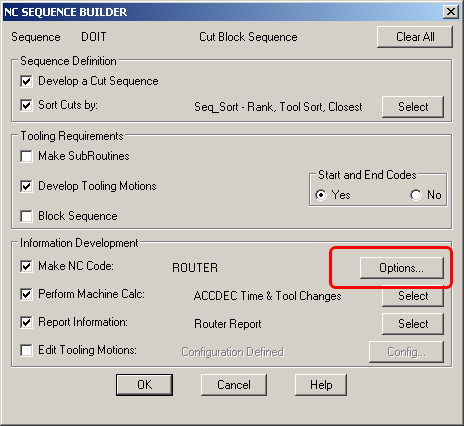

The NC Sequence Builder will appear, select OPTIONS to continue.

The Sequence Options window will be shown. In this window, you will need to specify a JOBID number, and also a material thickness. Set the options up like the following window.

The JOBID will allow a program number to appear in the code. The Material Thickness field will allow you to set the material height so that when you touch off your tools to the top of the spoil board, all the Z depths will be correct. Select OK when you are finished placing the values for JOBID and Depth.

You will see the NC Sequence Builder again, select OK to make the nc code for the part.

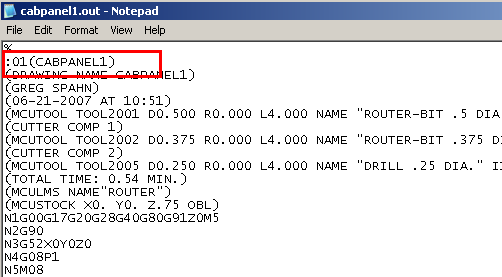

The code will appear on the screen allowing you to view it. If you look at the beginning of the code file you should see the JOBID number at the beginning.

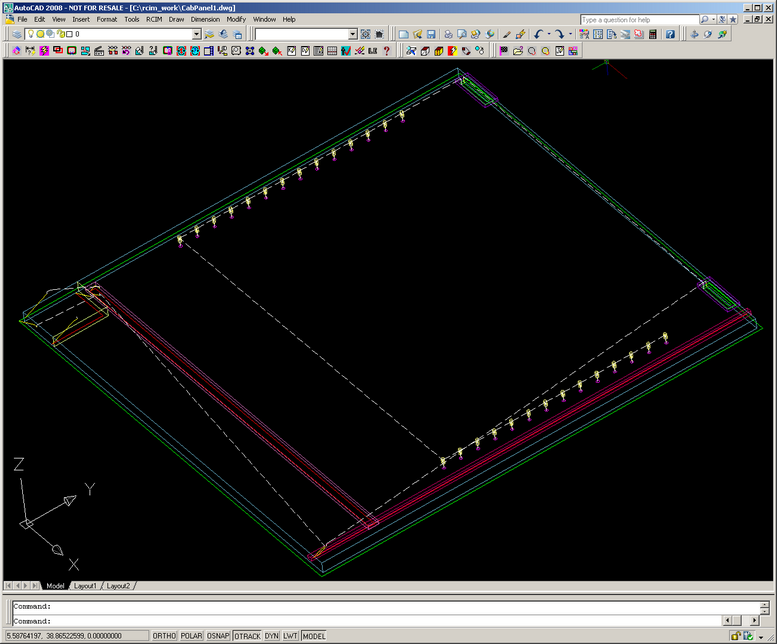

You can close the code and see the Sequence on your part on the screen.

The process learned here is to import knowledge and set up a DOIT File to cut parts more quickly. In the next section, you will cut the next sample part more quickly.

You can close the Autocad that is open and then continue to the next section.