|

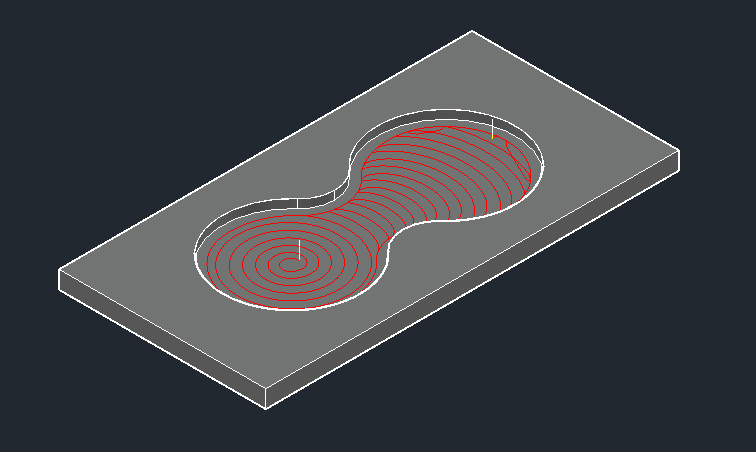

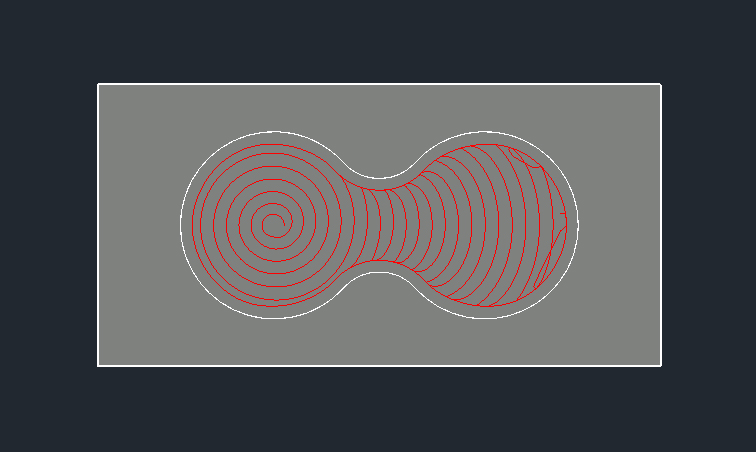

This version of Advanced Pocketing uses adaptive roughing algorithms based on the wire frame input geometry and contains many options to control the creation of the tool path than the other pocketing cycles. This adaptive strategy ensures that the cutting conditions remain almost constant by measuring the engagement volume of the tool with material and gradually removing material off the remaining stock. It guarantees stables load on the tool allowing for increased material removal rate at higher feed rates and reduces overall machining time.

|

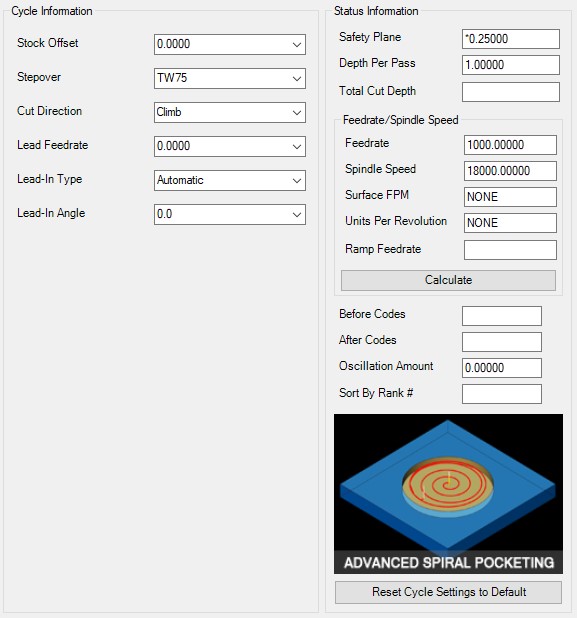

The following parameters effect the toolpath creation:

The value entered here will be added to the cut offset to provide material left for a clean up pass on the pocket with a separate tool.

This value defines the stepover made after each offset.

1) Default of TW75 will step over by 75% of the tool diameter

2) Number followed by the % sign. This needs to be entered as a percent number such as 25% or 50%. This will stepover the percentage of the tool diameter

3) Number only. You can identify a specific stepover offset by just putting in the value as long as it does not exceed the diameter of the tool. Value of 0.25 would stepover 0.25 regardless of the tool diameter.

The value represents if the cutting cycle will be doing Climb (CCW) milling or if you want the cutting cycle to do Conventional (CW) milling when pocketing inside geometry.

This sets lead-in and lead-out feed rates. The default is 50%. Setting this parameter to any number will override the lead-in feedrate to the number specified. Setting this parameter to a percentage, 25% (must include the % symbol) will adjust the lead-in based on the feedrate identified by the percentage defined on CNC machines with this capability.

This parameter defines the type of entry move the toolpath will make when making its initial approach.

The possible options are:

1) Automatic – The approach type will be picked automatically to avoid collision

2) Line – The ramp move is a slanted line when a Lead-In Angle is used

3) Helical – The ramp move is helical

|

|

|

Lead-in Line No Angle |

Lead-In Line 30 Degree Angle |

Lead-In Helical 30 Degree Angle |

The parameter will need a numeric value defining the degrees of the ramp such as 30 or 45.

**Changing values in the cycle parameters may yield unexpected results with some settings or on some geometry. Examine the toolpath and NC Code carefully before running your machine tool if you change these default settings.