Some geometry could cause issues that are not readily detectible until the part is run on the machine. Other geometry can cause issues that are readily apparent when a tool path is created.

Crossing Geometry:

It is important to note that lines and arcs that cross other lines and arcs could confuse the Shapes command.

When lines and arcs have the same end points, the shape could go in several directions. Keep all geometry to be Geoshaped clean and continuous without ambiguous end points.

The easiest way to see incorrectly shaped geometry is with the Start Point Edit command. If you have a shape that is supposed to be closed and Router-CIM is finding more than one Start Point, or if the Start Point will not change, then the geometry is not closed and should be repaired before going any further. The location of the X is where a problem exists in the geometry.

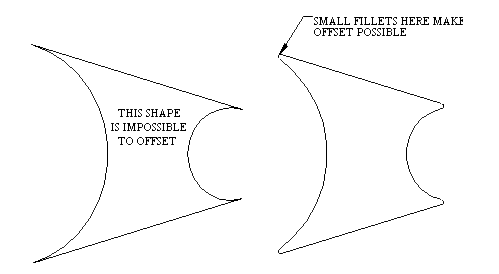

Impossible Offsets:

Certain geometry is impossible to offset. Under certain circumstances, you may have to insert a Fillet or Chamfer to allow offset. These situations occur when arcs and lines cannot connect when offset. The Fillet or Chamfer will usually solve this problem. Use the smallest acceptable radius or distance.