![]()

When selected, this option will create a tool path that varies its depth in the Z Axis constantly throughout the Cut. This ensures that the cutter will not be subjected to sustained frictional pressure at any one location, such as at the point where the cutter contacts a laminated surface.

Entering an amount in this parameter will produce a tool path that continually ramps either up or down until it reaches the depth given in the Total Depth field if the number is positive , or the depth of the Cut minus the Oscillation Amt if the number is negative.

The following example will produce Cuts of various depths to allow for minimum tool wear and minimum removal of spoil board material.

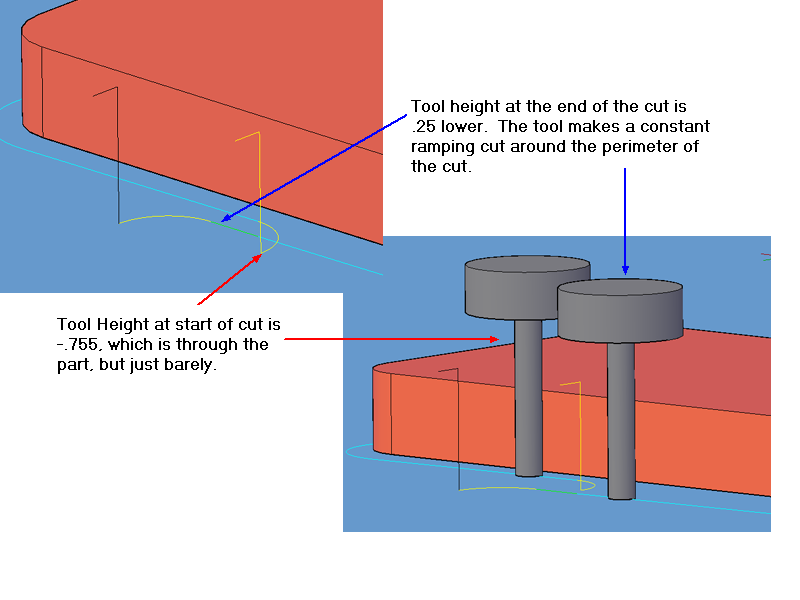

EXAMPLE 1:

Material is ¾" thick.

| • | Set Total Depth to -1.05 |

| • | Set Oscillation Amt to 0.25 |

The cutter will enter the material and proceed to the Total Depth of -1.0. It will then gradually lift up, in the Z Axis until it has reached a Z depth of -.75 by the end of the Cut.

Any laminate or other characteristic of the material that would have caused heavy wear to one portion of the cutter has been distributed over ¼" of the cutting surface (which is the amount entered into the Oscillation Amt field).

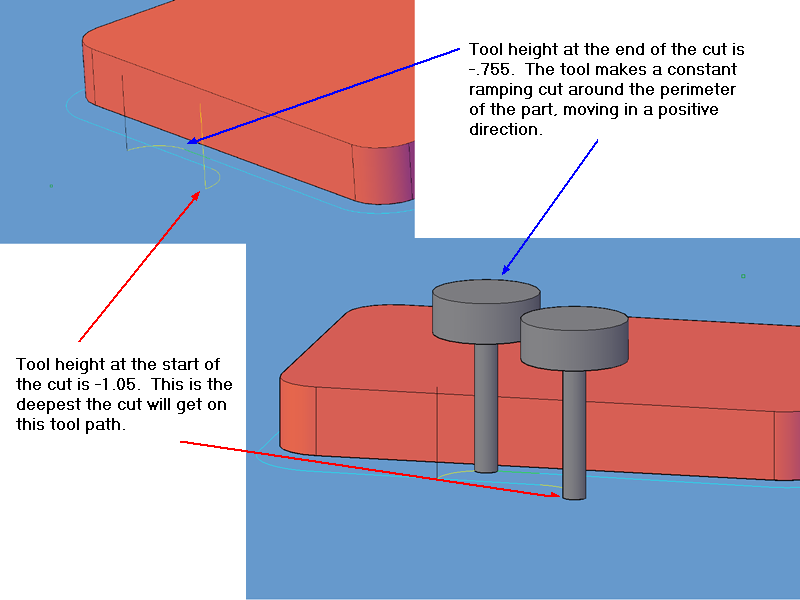

EXAMPLE 2:

Material is ¾" thick.

| • | Set TOTAL DEPTH to -.755 |

| • | Set OSCILLATION AMT to -0.25 |

The cutter will enter the material and start the Cut at -.755. It will then increase the depth until a total of -1.05 at the Cut end, and then retract.