Closed Polyline Flow Cutting is provided to satisfy cutting situations best handled by a continuous spiraling toolpath, that is guided within an area defined by two closed polylines. Creating the two polylines is typically this is accomplished by creating a polyline from the edge of the solid and then offsetting it the appropriate amount for the tool. These closed polylines must be going in the same direction and the Start Points of both polylines must be aligned. These conditions are easily met by using Geoshape and Start Point Edit on the two polylines planned for use with this cycle. Geoshape will insure the polylines are going in the counterclockwise directions and Start Point Edit will allow you to align the two start points.

The Flow Cutting cycle will follow the direction of the two polylines, so you can use the command NCREVDIR to reverse the direction of the two polylines if desired.

Since there is nothing to contain the tool path when it meets the bottom of the shape, we will use the Nurbs Working Area settings to define the top and bottom of the shape so that the tool path does not go below the bottom of the part.

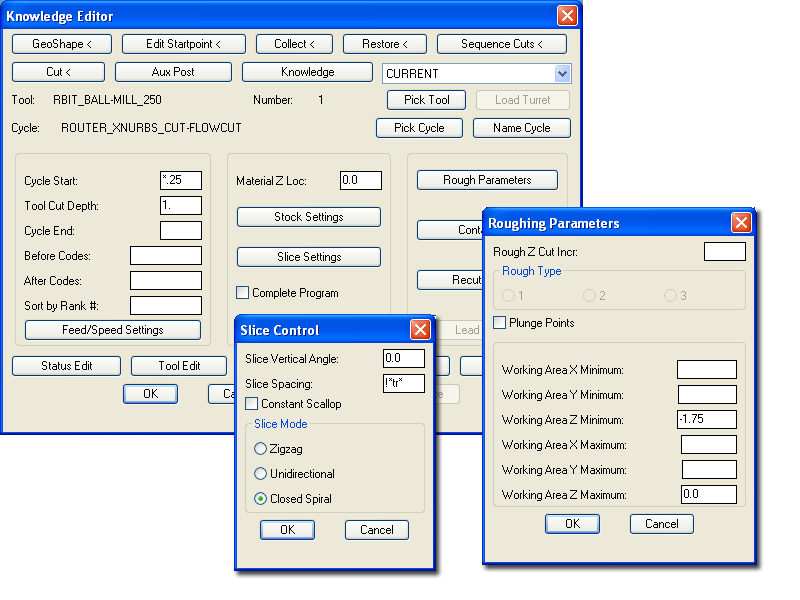

Open MCADCLFLOW.dwg and start Router-CIM. Change your knowledge settings to match the ones below:

The Roughing Parameters window will allow you to set the Working Area minimum and maximum so that no tool paths cross beyond these areas. Set the Z Maximum to 0.0 which is the top of the part and the Z Minimum to -1.75 which is the bottom of the part and then no tool paths will fall below the part.

Setting the Slice Mode to Closed Spiral will allow the tool path to make a constant spiral pass without lifting up to the Safety Plane until it reaches the end of the path.

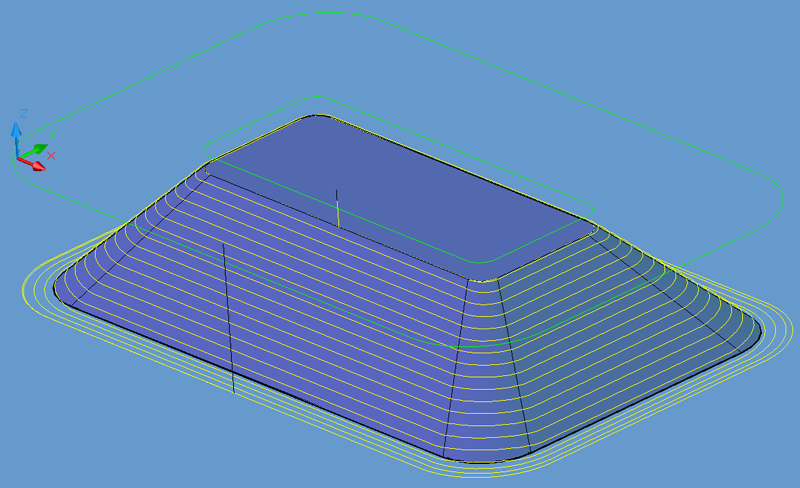

Change your settings to match the ones here and then make a cut, selecting the solid as the shape to cut and the two green polylines as the Flow Lines. If prompted to redefine the surfaces, answer Yes. Your results should look like the one below:

This tool path starts at the top of the part, on the boundary of the inner flow line, and makes one tool path constantly stepping down in Z while circling the part until it reaches the minimum Z depth set in the Roughing Parameters and then continues at that depth until it reaches the outside flow line.