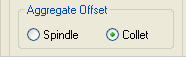

This parameter is the offset type of a horizontal tool path and applies only when making Horizontal Cuts. This type of offset is dependent on the settings that are available to the programmer/operator when programming and running the machine. The control of the cut and tools can be solely placed in the program to accomplish all the machine offset moves or it can be placed in the machine, or a combination of both.

If Spindle is chosen as the aggregate offset, the cut path will appear on the screen to be offset by the amount designated in the Tool Length parameter.

If Collet is chosen, the cut path will appear inside the part the distance designated in the Total Depth parameter on the Control Panel. This method requires that you either set the work coordinate to the tip of the tool, or set the distance from the tip of the tool to the center of the spindle in the horizontal tool length offset and use Plane Detect.

The Combination of Spindle and Collet methods

There is a third choice for using a horizontal drill. It is probably the easiest for both the programmer and operator alike. This method requires that you are cutting on one of the 4 faces of the part and not some arbitrary angle, and also for the programmer to know the distance from the center of the drill block to the face of the collet that the tool fits into. It then requires the operator to measure how much tool is sticking out of the collet in the drill block.

The programmer places the distance from the center of the spindle (where the work coordinate is set) to the face of the collet in the Tool Length.

The operator placed the tool length (the amount of the tool sticking out of the collet) into the horizontal length offset.

This method allows for the programmer to only need one number that never changes for a tool length, and the operator can measure the amount from the collet to the tip of the tool (with almost any measuring device) and put it in an offset, just like he/she would for any other tool touched off.