|

The Drill Motions cycle is the standard drilling cycle in Router-CIM. With Drill Motions, you can drill in one pass, or in several passes with pecking motions.

By default the tool will rapid to the safety plane above the hole, then feed in to the depth of the cut and then rapid out of the hole back up to the safety plane. If you wish to peck drill the hole, you can set multiple depths per pass (peck increments) and the tool will rapid to the hole, feed down to the first depth, the rapid back to the safety plane, then rapid back down to .1 above the next material to be cut, then feed down to the next depth of cut, rapid up to the safety plane, etc. until it finishes the hole.

The drill motions cycle has very few parameters that can be changed as it is the most basic drilling cycle in Router-CIM. |

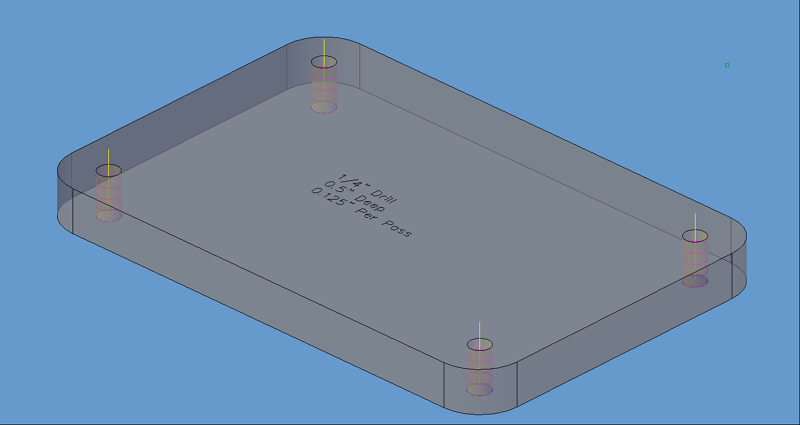

Drill Motions cut cycle.

The following parameters effect the toolpath creation:

Adding a Dwell/Pause at the end of a Drill Cycle

To add a dwell/pause at the bottom of a Drill Motions cycle, you will need to adjust the following setting in the Drill Motion cycle:

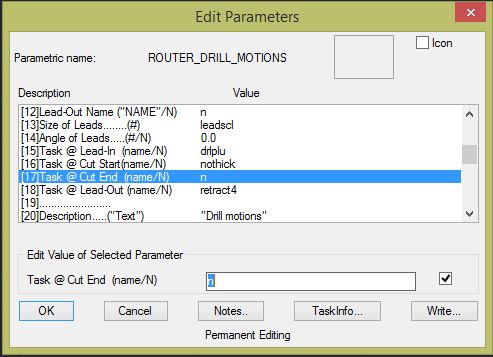

To make this change, go to the Router-CIM Control panel in AutoCAD and select the button for 'Mod Cycle'.

Change Position 17, 'Task @ Cut End (name/N)' in the Drill Motions cycle to DWELL/1 (or the time you want to pause, in seconds). You will get a G04P1 in the code after the tool is at cut depth.

Alternately on newer posts, you can use DWELLX/.1 and get G04X.1.

To make this change, select Position 17, 'Task @ Cut End (name/N)', type in the new value as stated above and hit 'Enter'. You should see the value update in Position 17.

Note: To know which option is right for you, please review your Post Processor's Application Notes.

**Changing values in the cycle parameters may yield unexpected results with some settings or on some geometry. Examine the toolpath and NC Code carefully before running your machine tool if you change these default settings.