Cutter Compensation will accept 1 of 3 selections: Yes, No, or Both, explained below.

Note: A thorough understanding of Cutter Compensation is very important. Consult your CNC control's Operator's Guide for more information on G41, G42, & G43 or your machines specific offset calls.

Note: CNC controls may require different code other then the ones listed. These will be determined by the post processor created for your specific CNC control type. Please refer to the post processor application notes that were included when the post processor was installed.

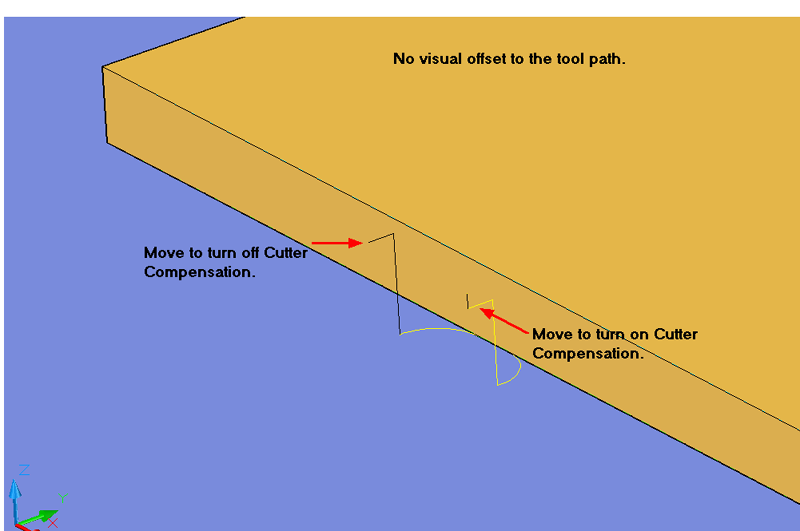

Cutter Comp YES

When using this option you will see the tool path directly on top of your part geometry.

The code that is produced reflects the part profile with compensation. At the machine, the entire tool radius must be placed into the offset register.

Your code will have the G41 or G42 with an offset register number, such as D01, and a move to turn off the compensation with the G40 code.

Cutter Comp. YES

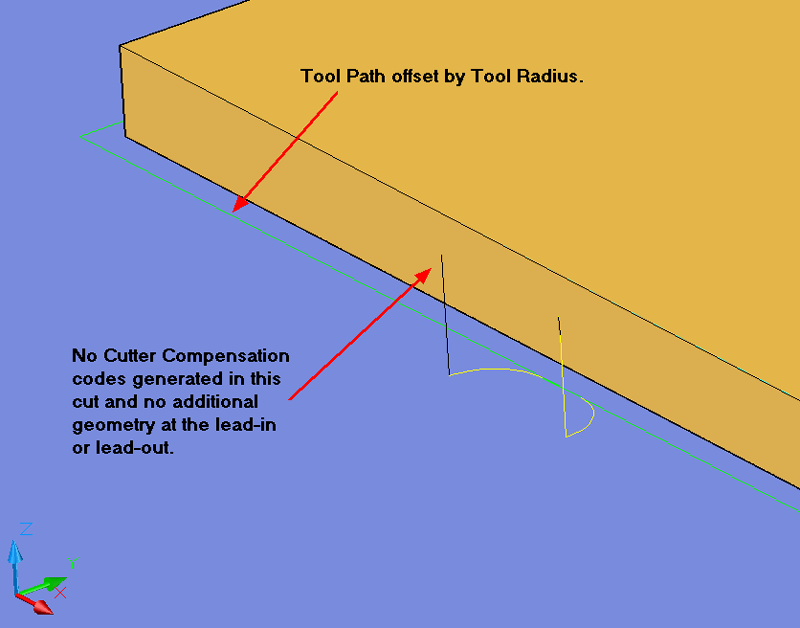

Cutter Comp NO

Using this option will generate a tool path that is offset by the radius of the tool as it appears on the Control Panel in the Tool Radius parameter.

This option does not generate a Cutter Compensation code (no G41/G42/G40 or D numbers).

Typically No is used for drilling, surface cutting, pocketing and engraving.

Cutter Comp. NO

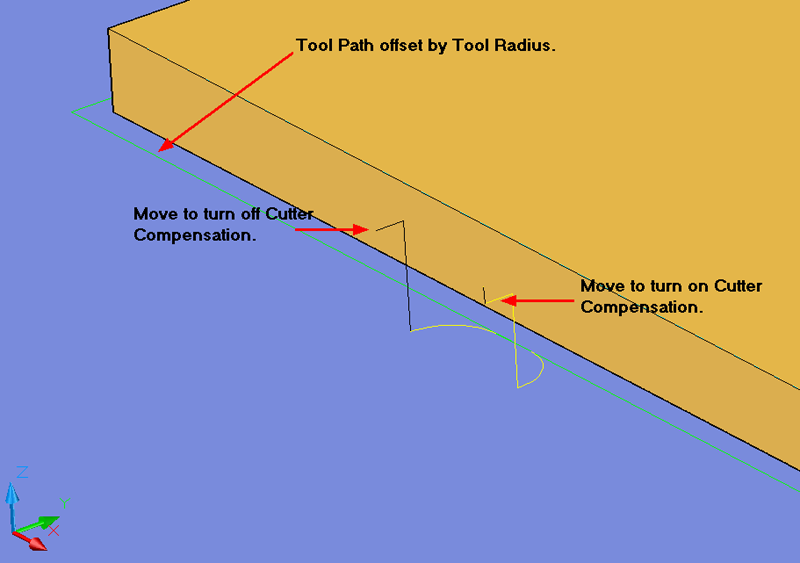

Cutter Comp BOTH

This option will show the tool path offset by the radius of the tool as it appears on the Control Panel in the Tool Radius parameter.

Note: Some CNC controls will not allow this option to be used. Please refer to the post processor application notes that were included when the post processor was installed to see the available options for your CNC control.

Both will generate a G41/G42 also, along with a D number and a G40 to cancel the compensation. The wear amount of the tool is then input into the offset register (D#) at the machine.

This option provides the best results because you can visually inspect the offset on the screen, and compensate for tool wear. Typically used for all contour cutting.

The B for Both choice is useful, because you input a D value at the machine that is the difference between what Router-CIM offsets and what the tool radius actually is (usually a very small amount). Measure the tool radius and add or subtract that value from what was offset (nominal radius), and then place that difference into the appropriate D register (the offset page at the controller). You should program most cuts with Cutter Compensation using Yes or Both. Only by using Cutter Compensation can you adjust for sharpened or worn bits as well as to parts cut with different sized bits.

Cutter Comp. BOTH