|

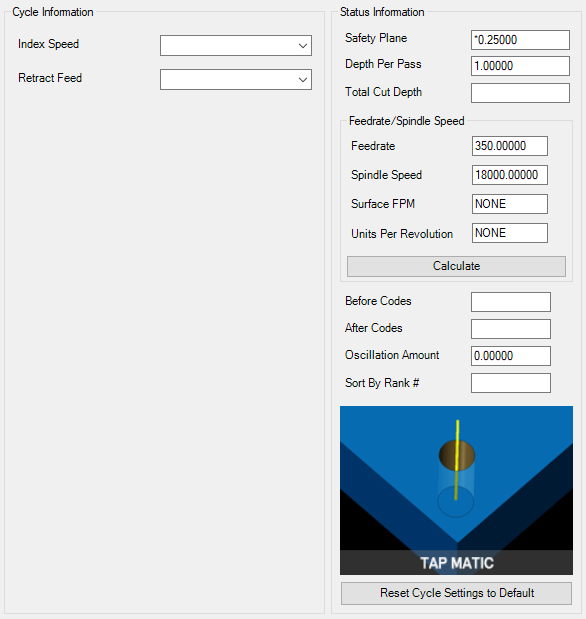

The Tap Matic cycle is used to program a drill type motion for a Tap Matic head fitted to a spindle on the machine. The Tap Matic head requires a feedrate for the motion down into the hole, and another feedrate on the way back up out of the hole.

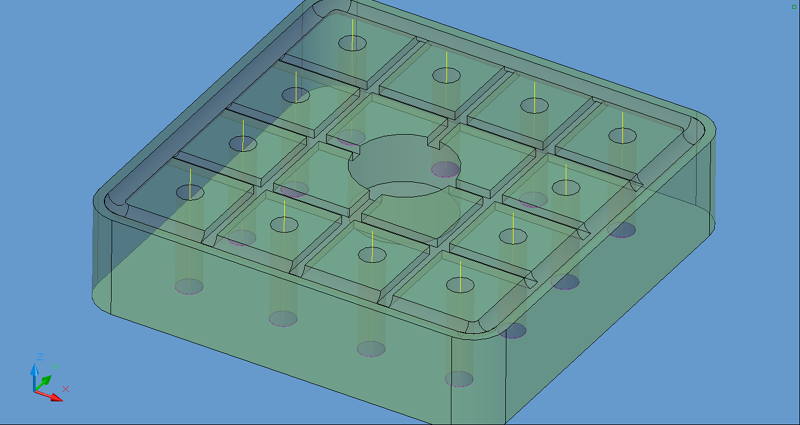

Router-CIM provides for the separate feedrates in its drill motions using this cycle so that the Tap Matic head can be used. The geometry needed is simply a circle, geoshaped, and otherwise the cycle works the same as Drill Motions. |

The following parameters effect the toolpath creation:

Index Speed

This is the fastest speed that you want the machine to achieve between the drilled holes. This feedrate will take place of the rapid traverse move between cuts and during the retract of the hole. If the machine can make a fast linear move between the cuts, usually this will reduce the overall cycle time of the drill moves.

This cycle has a separate feedrate for the lead-out. You should specify the lead-out feedrate in this position.

**Changing values in the cycle parameters may yield unexpected results with some settings or on some geometry. Examine the toolpath and NC Code carefully before running your machine tool if you change these default settings.