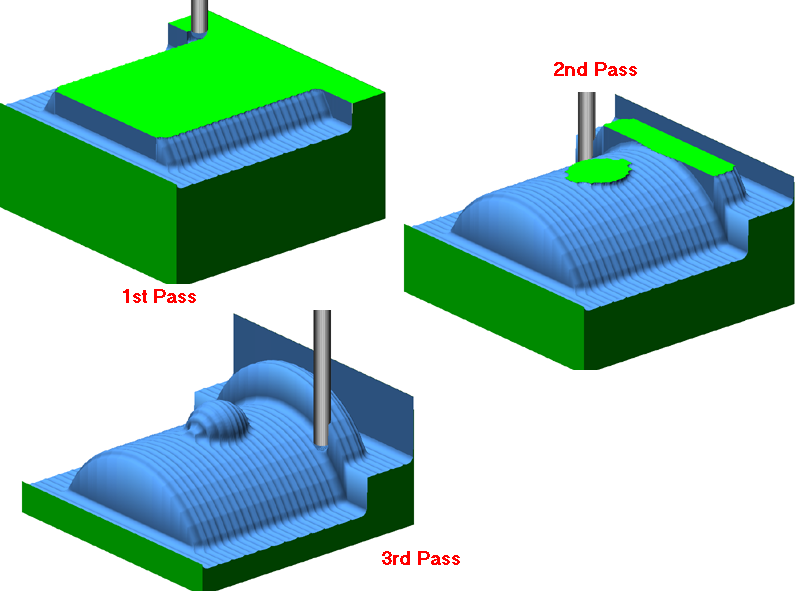

This method is efficient if the tool can load and unload during the cut, and the indexing during some of the passes is not prohibitive to the tool or part.

In this case the first pass removes some material from the sides of the block, but spends some time indexing to the next cut position, before dropping down to the second level. The second level keeps the tool in the material for all but the top of the dome, and the third level keeps the tool in the material the entire time for the last rough pass.

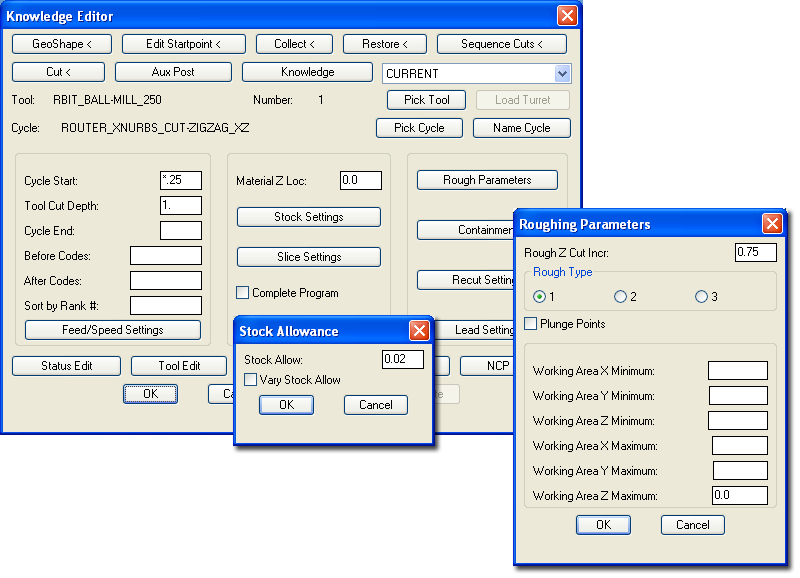

These settings can be used with either the Zigzag XZ or Zigzag YZ cycles.

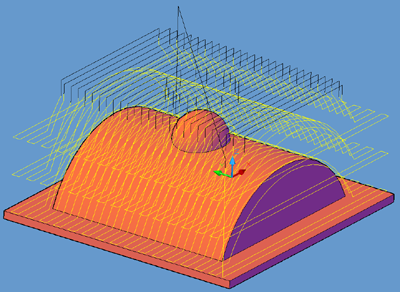

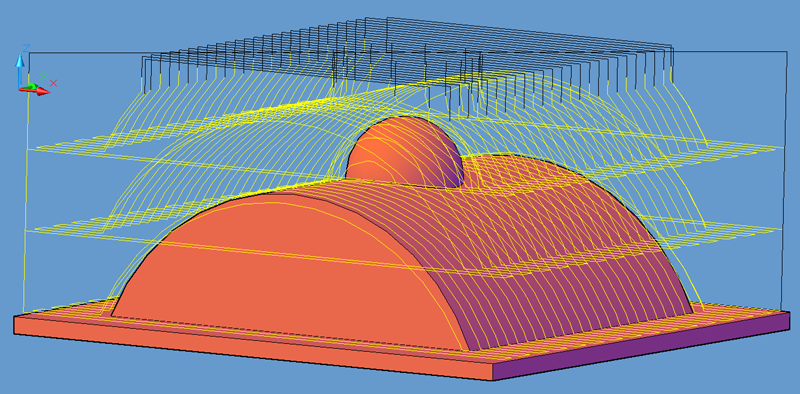

Using the MCADTPC.dwg and the following parameters, a similar roughing pass can be created.

These roughing passes show where the tool lifts up and indexes over to the next cut position, only removing material from the part if it exists at that particular Z level. If the step down in Z was smaller, the top few passes would index at the Safety Plane for some of their cuts, but the bottom passes would constantly be in material.