|

Linear Unidirectional Pocketing will create a linear pocket cut with the tool cutting in one direction. At the end of the cut the tool will retract, move back to the start of the next pass, then plunge and cut in the same direction as the last cut, retract, and start over.

This is a useful cycle when the geometry of the tool or condition of the material will only permit a satisfactory finish with the tool cutting in one direction (climb or conventional milling).

There is a provision for a separate finish pass at the end, which will follow the contour of the entire shape to clean up any tool marks on the edge of the cut.

Download sample drawing here. |

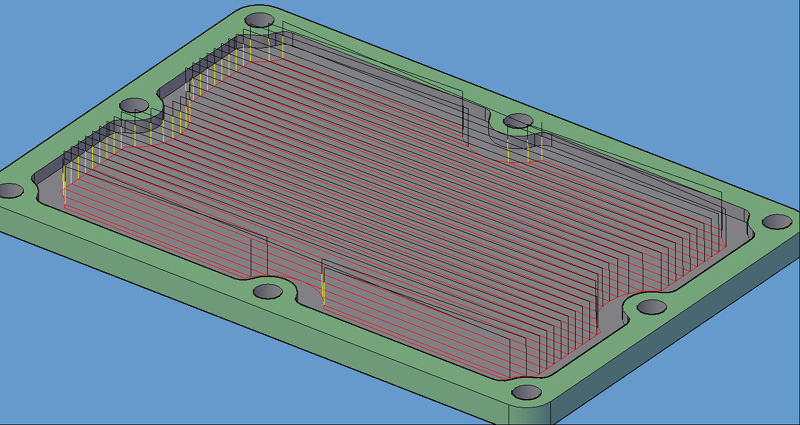

Linear Pocket Unidirectional tool path.

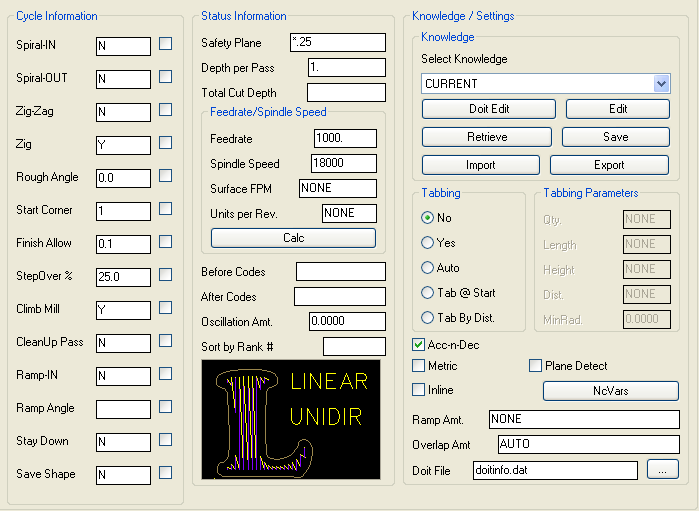

Linear Pocket Unidirectional parameters.

The following parameters effect the toolpath creation:

Spiral-IN

Spiral – OUT

Zig-Zag

Zig

Rough Angle

Start Corner

Finish Allow

Step Over %

Climb Mill

CleanUp Pass

Ramp-IN

Ramp Angle

Stay Down

Save Shape

Safety Plane

The safety plane is the index plane Z location. If a ' * ' is used as the first character, that position is absolute in world Z coordinates, otherwise it is considered to be the distance above the shape.

Depth Per Pass

This controls the depth per pass in Z. It is also the initial Peck Increment.

Total Cut Depth

This parameter controls the total depth of the cut. If a ' * ' is used as the first character, that position is absolute in world Z coordinates. If it does not, then that distance is considered to be the distance below the initial shape.

Feedrate

Initial feedrate to start the drilling operation.

Spindle Speed

The RPM value to use for the spindle for this tool path.

Before Codes

Values placed here will be output in the cut cycle before the tool enters the material, typically at the height of the Safety Plane once the tool length compensation is set.

After Codes

Values placed here will be output in the cut cycle after the tool has retracted from the cut, typically at the height of the Safety Plane after the cut is finished.

Sort by Rank #

A numeric value to use for the tool path created to allow the Sequence to place cuts in a specific order when the code is created.

**Changing values in the cycle parameters may yield unexpected results with some settings or on some geometry. Examine the toolpath and NC Code carefully before running your machine tool if you change these default settings.