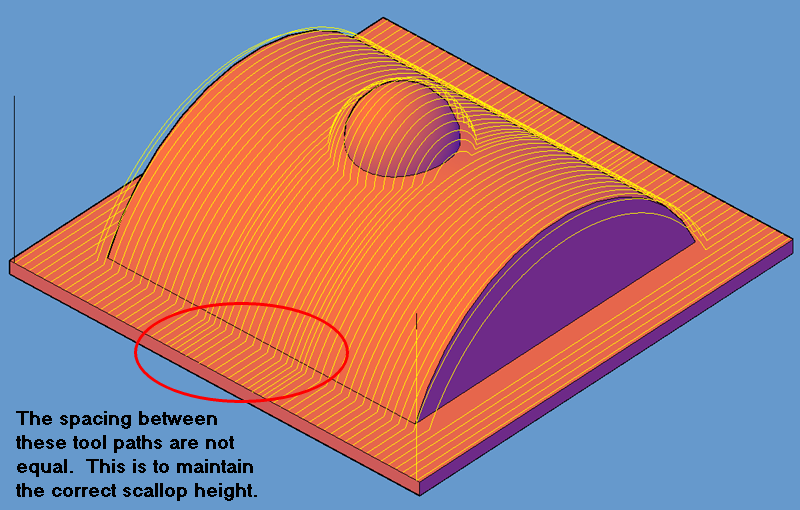

Scallops are the ridges left behind from the cutter stepping over in X or Y to cut the next pass. A Ball Mill will always leave a small scallop. The size of that scallop can be specified as a height, and Router-CIM will calculate the step over spacing between each pass to maintain that scallop height. Some tool paths will be placed closer together than others, especially if they are by a sloped surface where the tool has to maintain the scallop height while moving up or down as well as in X or Y.

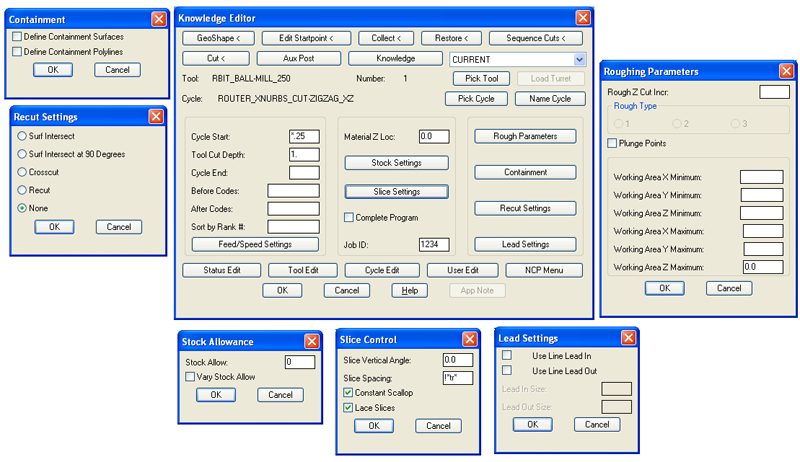

Activate the Cut Button after duplicating the Knowledge Editor entries shown below using MCADTPC.DWG, to achieve similar results.

When prompted during CUT, enter .005 for Scallop Height and .001 for minimum step size. If prompted to Define New Surfaces, select Yes.

These settings will produce a tool path that has varied step over amounts wherever the tool needs to space the tool paths out differently to maintain the scallop height specified. Even though the Slice Spacing was set to !*tr* (Tool Radius) the same as the last two, the tool paths are clearly set to an amount very different from that specified so that they can maintain the scallop height of .005". In addition, they are much closer together at the edges of the sphere on top because the tool must step over less in this section to maintain the scallop height.

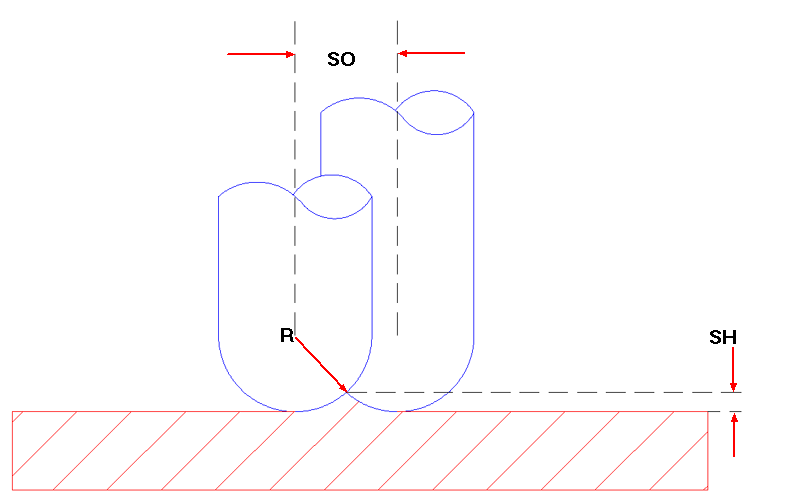

Router-CIM will maintain the Scallop Height indicated throughout the tool path created. If you want an idea of how much to set the scallop height to or what the step over amount would be, there is a formula to calculate the scallop height:

R = Cutter Radius

SO = Step Over

SH = Scallop Height

![]()

Or another way to express this would be:

SH=(R-(Sqrt ((R**2) - ((SO/2)**2))))