This means that if you were to drill several holes on the side of a shape, you would have the drill moving back up to the safety plane on each hole. This is mainly for safety as sometimes programs are stopped and restarted in locations that could cause a collision if the tool is left down at the hole depth.

If you want to avoid the extra moves in Z, you could simply group the holes on each side of the part after they are geoshaped and then drill them. This will create one Z move down and leave the head at that Z location and then move between each of the holes, returning to the Z height of the safety plane when the holes are done.

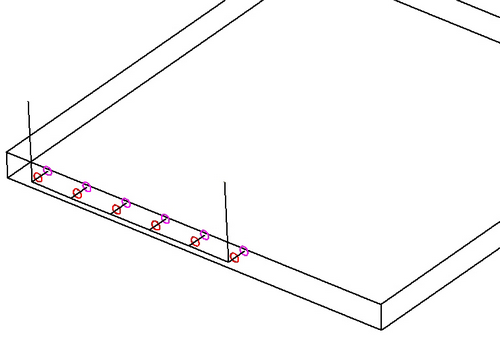

This is how the cycle would look when the holes are drilled:

This would work with either a horizontal drill in a drill block, or an aggregate tool drilling on the side of a part. If Plane Detect is turned on, only one horizontal comp move will be generated as well.

The code would look like this:

%

:1234(HBORING)

N1G00G17G20G28G40G80G91Z0M5

N2G90

N3G52X0Y0Z0

N4G08P1

N5M08

N6(DRILL .25 DIA.)

N7G53C90.

N8G28G91Z0M05

N9G90T2003M06

N10T102

N11M03S18000

N12G00G17G54P43X1.Y-.25C90.

N13G00G43H3Z2.

N14G18G44H83

N15Z-.375

N16G01Y.375F150.

N17G00Y-.25

N18X2.2598

N19G01Y.375F150.

N20G00Y-.25

N21X3.5196

N22G01Y.375F150.

N23G00Y-.25

N24X4.7794

N25G01Y.375F150.

N26G00Y-.25

N27X6.0392

N28G01Y.375F150.

N29G00Y-.25

N30X7.299

N31G01Y.375F150.

N32G00Y-.25

N33G00Z2.

N34H0

N35G53C90.

N36G28G91Z0M5

N37G28G91X0M09

N38G90

N39G52X0Y0Z0

N40G08P0

N41M30

%